Thermal Metamaterials: Rewriting the Rules of Heat Management

In the ever-evolving landscape of technology, a groundbreaking innovation is poised to revolutionize how we manage heat in electronic devices. Thermal metamaterials, a cutting-edge class of engineered materials, are challenging conventional wisdom and opening up new possibilities for efficient thermal control. As our gadgets become more powerful and compact, the need for advanced heat management solutions has never been more critical. Enter thermal metamaterials – the unsung heroes that could reshape the future of electronics.

The Science Behind Thermal Metamaterials

At their core, thermal metamaterials are composite structures designed to exhibit thermal properties not found in naturally occurring materials. These materials are typically composed of carefully arranged patterns of different substances, each with its own thermal characteristics. The magic lies in the precise arrangement of these components, which allows for the manipulation of heat flow at a microscopic level.

The key to thermal metamaterials’ extraordinary capabilities is their ability to control the propagation of phonons – the quantum particles responsible for heat conduction in solids. By creating intricate structures that interact with phonons in specific ways, scientists can guide, block, or enhance heat flow with unprecedented precision. This level of control opens up possibilities for directing heat away from sensitive components, creating thermal cloaks, or even harvesting waste heat for energy production.

Breaking the Rules of Thermal Conductivity

One of the most fascinating aspects of thermal metamaterials is their capacity to defy conventional rules of heat transfer. Traditional materials conduct heat uniformly in all directions, but thermal metamaterials can be designed to conduct heat preferentially along specific paths. This anisotropic thermal conductivity allows for the creation of thermal diodes and switches, devices that can control the direction of heat flow much like electronic components control the flow of electricity.

Furthermore, thermal metamaterials can exhibit negative thermal expansion, a property where materials contract when heated instead of expanding. This counterintuitive behavior can be leveraged to create materials with zero thermal expansion, crucial for applications requiring dimensional stability across a wide temperature range, such as space telescopes or precision measurement instruments.

Applications in Electronics Cooling

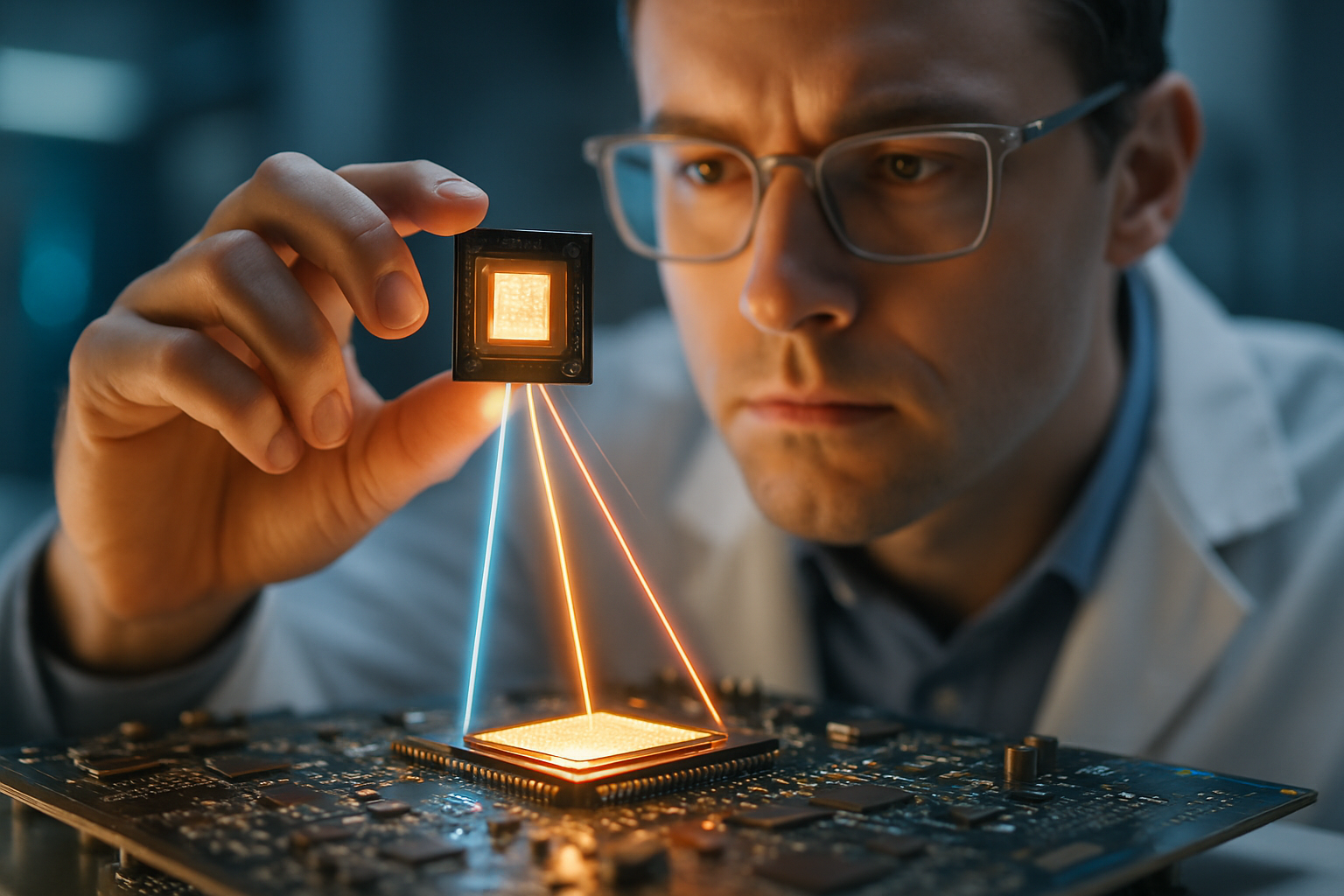

As electronic devices continue to shrink while growing more powerful, efficient heat dissipation has become a critical challenge. Thermal metamaterials offer a promising solution to this problem, potentially revolutionizing the way we cool our gadgets. By incorporating these materials into device designs, engineers can create more effective heat sinks and thermal management systems that occupy less space and operate more efficiently.

One exciting application is the development of ultra-thin thermal spreaders. These components, made from carefully designed thermal metamaterials, can rapidly distribute heat across a larger surface area, facilitating more efficient cooling. Such innovations could lead to slimmer, more powerful laptops and smartphones that run cooler and longer on a single charge.

Beyond Electronics: Wider Implications

The potential of thermal metamaterials extends far beyond the realm of consumer electronics. In the automotive industry, these materials could enhance the efficiency of electric vehicle battery packs by managing heat distribution more effectively. In the construction sector, thermal metamaterials could revolutionize building insulation, leading to significant energy savings in heating and cooling.

Perhaps one of the most intriguing applications lies in the field of thermoelectric energy harvesting. Thermal metamaterials could dramatically improve the efficiency of devices that convert waste heat into electricity, potentially recovering vast amounts of energy that would otherwise be lost to the environment. This technology could find applications in industrial processes, power plants, and even wearable devices that generate electricity from body heat.

Challenges and Future Outlook

Despite their immense potential, thermal metamaterials face several challenges on the path to widespread adoption. Manufacturing these complex structures at scale remains a significant hurdle, often requiring sophisticated and costly production techniques. Additionally, many thermal metamaterials currently rely on exotic or expensive components, limiting their practical applicability.

However, ongoing research is rapidly addressing these challenges. Scientists are exploring new fabrication methods, including 3D printing and self-assembly techniques, to simplify production. Additionally, efforts are underway to develop thermal metamaterials using more common and cost-effective materials, bringing this technology closer to commercial viability.

As research in this field accelerates, we can expect to see thermal metamaterials making their way into various products within the next decade. From more efficient data centers to self-cooling smartphones, the impact of this technology on our daily lives could be profound. The future of heat management is here, and it’s rewriting the rules of thermal engineering as we know it.